Even though many people refer to any waterproof/breathable (WPB) fabric as "GORE-TEX," your breathable rain jacket today might be made from any one of dozens of technologies. Regardless of branding, all WPB fabrics are engineered to juggle two tasks:

- Block precipitation to keep you and your clothing layers dry.

- Provide an escape route for perspiration vapor to keep clothing dry, and to help you maintain a comfortable body temperature during exertion in any conditions.

Waterproof/breathable technology, which debuted when the first GORE-TEX® jacket was introduced in 1978, has grown more advanced and complex over the years. This article will explain key terms, give an overview of how waterproof/breathable technologies keep you dry and some of the testing that brands do on their rain gear.

Waterproof/breathable rain gear offers protection from the elements on a number of fronts:

- It keeps rain on the outside: Waterproof/breathable rainwear is constructed using a membrane or coating that serves as a barrier that rain cannot penetrate. The outer surface of most rainwear (known as the face fabric) is also treated with a durable water repellent (DWR) finish that keeps raindrops from soaking that surface and compromising the breathability of the underlying membrane or coating.

- It helps you stay dry on the inside: The same membrane or coating that blocks rain also moves evaporating sweat through it. This is critical because you can also get soaked if you're exerting yourself and your sweat vapor can't escape.

- It also provides wind protection: The good news is that a jacket that's waterproof will also protect you from wind chill. In almost every case, a jacket that meets a waterproof test standard would also pass a test for being windproof.

For a more straightforward discussion of your rainwear options, see the REI Expert Advice article, How to Choose Rainwear.

How Waterproof Technology Keeps Rain on the Outside

Rainwear uses one of the following constructions to become waterproof and breathable:

- Laminates: A waterproof/breathable membrane is bonded to the underside of a garment's shell fabric much like wallpaper is applied to a wall—membrane (wallpaper) + fabric (wall) = a laminate. Because it's a durable construction (the membrane is protected by the face fabric), a laminate is found in outerwear designed for extreme environments.

- Coatings: A waterproof/breathable film is spread across the inner surface of a shell fabric—like a thin coat of paint on a wall. Coated constructions are lighter and more affordable than laminates—the tradeoff may be lesser performance and durability than a laminate.

Laminate and Coating Constructions

Because they are so thin, laminates and coatings need added protection against abrasion and contamination from dirt. That's why waterproof/breathable technologies are characterized as 2-layer, 2.5-layer and 3-layer, though those terms can be a little confusing:

- 2-Layer (casual) jackets: Found on less technical jackets, 2-layer construction bonds a waterproof/breathable membrane to the underside of an outer fabric. A hanging liner protects the membrane on the inside.

- 3-Layer (performance) jackets: Found on the best (and most expensive) jackets, 3-layer construction is similar to 2-layer in that the waterproof/breathable membrane is bonded to the underside of an outer shell fabric. On the inside, though, another fabric layer is also bonded to the membrane to protect it. This construction (though it sounds counterintuitive) allows a 3-layer jacket to be much lighter than a 2-layer jacket because it doesn't include the weight of the hanging liner.

- 2.5-Layer (affordable) jackets: How can you have half a layer? This construction starts with a waterproof/breathable coating on the underside of an outer shell fabric and then adds a thin protective veneer—the half layer—to protect that coating. A 2.5-layer jacket will typically be less breathable than either a 2-layer or 3-layer jacket, but it will also be less expensive. Because no inner fabric is required, some ultralight jackets might also have a 2.5-layer construction.

Be aware that branded waterproof/breathable technologies use a variety of approaches—not all GORE-TEX® fabric has a 3-layer construction, for example. Brands choose the construction method that best suits the intended purpose of the jacket. And, to confuse things further, brands don't all explain their technologies by describing them as a 2-, 3- or 2.5-layer construction. (The rainwear product specs you find on REI.com include those terms whenever the waterproof/breathable brand uses them.)

How to Choose Rainwear includes more information about laminates, coatings and layered constructions.

Water in the shape of a raindrop is thousands of times larger than water in sweat-vapor form. Micropores in your jacket's membrane or coating are large enough for sweat vapor to escape, but too small for rainwater to get through.

How Breathable Technology Helps You Stay Dry on the Inside

The key to how membranes and coatings can be both waterproof and breathable lies in the fact that water in the shape of a raindrop is thousands of times larger than water in sweat-vapor form. Micropores in your jacket's membrane or coating are large enough for sweat vapor to escape, but too small for rainwater to get through.

In addition, as you perspire, the air inside your jacket becomes hotter and more humid than the air outside your jacket. Nature prefers equilibrium, so that hot, moist air migrates through the micropores in the membrane or coating and into the cooler, less humid air around you.

How temperature and humidity affect breathability: Brands are evolving the performance of their proprietary waterproof/breathable technologies all the time, which is why today's rainwear performs much better than first-generation GORE-TEX® jackets. It's worth noting, though, that regardless of the waterproof/breathable technology, a profusely sweating human can generate heat and humidity that exceeds a jacket's ability to breathe. In cool weather, a waterproof/breathable jacket will do its job effectively. If you're exerting yourself in warm and steamy conditions, though, no rain gear is likely to feel comfortably dry inside.

What is Durable Water Repellent Technology?

The outer surface of rainwear has a durable water repellent (DWR) finish. This often-overlooked aspect of rainwear performs a key function:

- A DWR finish protects the face fabric from becoming saturated. It does so by causing water to bead up and roll off the garment's exterior.

- A DWR finish is critical to maintain breathability. If the DWR finish wears off, then a jacket's fabric can get saturated. The laminate or membrane below the face fabric will prevent water from penetrating any deeper, but that saturated face fabric now has become a water barrier that impairs breathability. A saturated fabric also feels cold, which people falsely perceive as dampness, leading them to believe their jacket's waterproofness has failed.

How DWR finishes work: DWR finishes lay down microscopic, tightly-packed vertical "spikes" on the outer surface of a jacket. This dense, spiky finish leaves no room for water to spread out, forcing it to form into round droplets that bead up and slide off the fabric.

Even though the finish on your rainwear is called a "durable" water repellent, it won't last forever. Performance diminishes with use as dirt, oils and abrasion degrade them, which allows water droplets to flatten, spread out and penetrate the underlying fabric. That's why it's important to wash and revive your DWR finish whenever you notice that raindrops are beginning to soak in, rather than roll off. To learn more read, Rainwear: DWR Care.

Understanding Rainwear Testing

Shoppers invariably ask us which jacket is the most waterproof or breathable. Though brands all extensively test their waterproof/breathable fabrics, you can't do a spec-by-spec comparison. The problem is that, unlike the sleeping bag industry and its temperature ratings, the rainwear industry hasn't agreed on test standards, nor is there a network of independent test labs to measure performance.

Waterproof Testing

Any fabric is considered "waterproof" when it reaches a certain level of water resistance. Water resistance lab methods are standardized, using a water column or hydrostatic pressure test. Results are stated in millimeters (mm) or pounds per square inch (psi). Brands simply don't agree on the result that makes a jacket fully waterproof.

The 3 psi Waterproof Standard: REI Co-op considers 3 psi (2,109mm) or higher to be rainproof (waterproof). Some brands might tout ratings of 10,000mm (14.2 psi) or more, which sounds impressive, but has questionable real-world relevance: Wind-driven rain comes down with a force of about 2 psi (1,406mm). You would have to be hiking in a hurricane—wind-driven forces of 10 psi (7031mm)—before such bulletproof rainwear would be needed.

Breathability Testing

Breathability ("vapor permeability" is the scientific term) claims by brands are even less meaningful because brands don't use a single test method, and don't agree on a desired test result for each of the test methodologies that are used.

Windproof Testing

Most brands promote any waterproof fabric as being windproof. Testing for wind resistance ("air permeability" is the scientific term) involves measuring the amount of air (in cubic feet) that can pass through a fabric in a set amount of time. Some brands convert that result to a miles-per-hour spec and consider a fabric to be "windproof" if it blocks airflow of 60 mph or more. When tested, invariably waterproof fabric turns out to also be windproof.

Rain Gear Use Tips

Other factors beyond rainwear's waterproof/breathable technology impact comfort. Here are a few adjustments you can make along the way:

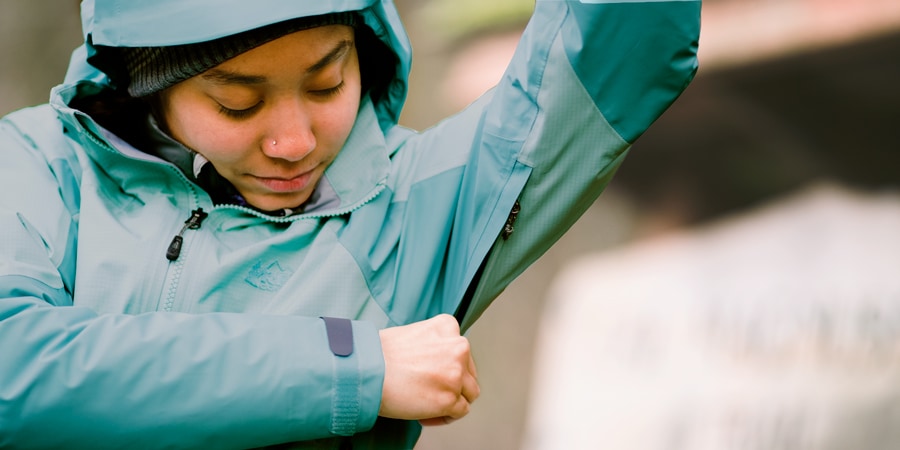

- Ventilate: If your rainwear has underarm zips and/or core vents, use them—along with your main front zipper—to speed sweat evaporation.

- Manage layers: Keep a light insulating layer handy for rest stops if you're cold; you can also shed an underneath layer if you're feeling overheated.

- Monitor exertion level: Slow down if your well-vented rain gear starts to feel like a sauna inside.

Rain Gear Care Tips

- Read and follow care instructions: Manufacturer directions supersede tips offered here.

- Wash rain gear regularly. A clean rain jacket outperforms a dirty one.

- Use specialized cleaning products created specifically for waterproof/breathable rainwear because they rinse away cleanly. Standard laundry detergents have additives that impact rainwear performance.

- Whatever cleaning product is used, always rinse thoroughly; doing two rinse cycles is a good way to be sure you remove all soap reside.

- Hand-washing or front-loading washers are preferred because a top-loader can snag a garment on its agitator.

- Close all zippers, empty all pockets and fasten all Velcro® closures to prevent possible abrasion while garments tumble. Turn garments inside-out.

- Things to avoid:

- Fabric softener and dryer sheets: Their additives diminish waterproof/breathable performance.

- Chlorine bleach.

- Dry cleaning.

- Open flames or intense heat because waterproof/breathable materials can melt.